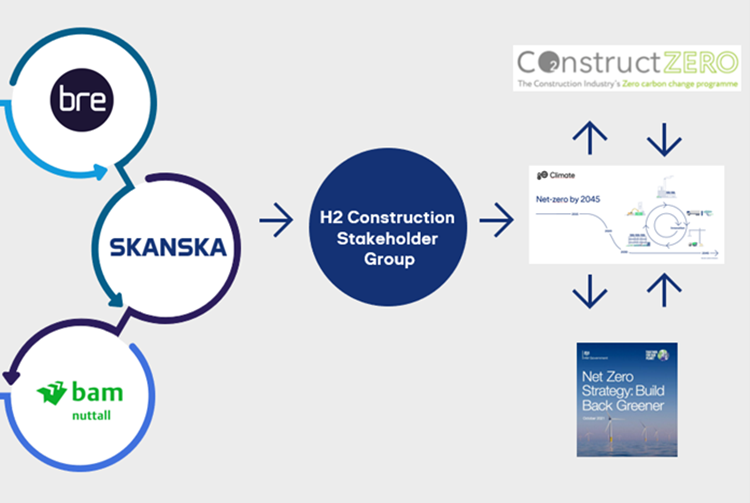

Led through a consortium-led collaboration between Skanska UK, BAM Nuttall and the Building Research Establishment (BRE), on behalf of Constructing Excellence the one-day workshop showcased current innovation and on-project trials as well as looking at the barriers we need to overcome to implement this new technology.

David Mason, Head of Environment Technical at Skanska explains why this collaborative approach is so important, “Achieving net-zero in the construction sector is a challenge on which Skanska has been leading the charge for many years, but we know it will never be solved by any individual organisation or solution, and that’s why collaborative events like this are so important. Sharing and learning about the steps contractors, our customers, partners and supply chain have been taking and identifying the key barriers to adopting hydrogen technology is critical to decarbonisation.”

Kamran Choudhury, Digitalisation Manager at Skanska says, "We are leading the construction sector’s transition away from diesel to sustainable power generation. This collaborative hydrogen stakeholder group, the first of its kind in the UK for construction, will highlight to industry just how zero-emission technology can be adopted to significantly accelerate decarbonisation.”

Chris Douglas, Senior Procurement Manager for Skanska’s Infrastructure operating unit adds, “Having a reliable supply of low carbon hydrogen is critical to getting powered plant and vehicles in use. Many of these partners were able to attend the event and played a significant role in developing our understanding of how to effectively stimulate investment and demand for zero emission plant. We were able to engage at all levels; with the major traditional fuel suppliers who are looking to move away from carbon-based fuels; UK and international manufacturers as well as specialists who are developing the technologies that need to be trialled and adapted for site use.”